26/01/2024

Understanding the Difference Between LCA and Carbon Footprint

Uncover the difference between LCA and carbon footprint. Embark on a journey of sustainability with our expert guide!

27 March 2024

The principle of sustainability has become deeply integrated into all aspects of production and manufacturing, with packaging playing a prominent role because of its significant environmental footprint and visibility to consumers.

Life Cycle Assessment (LCA) emerges as a comprehensive approach, evaluating the environmental impacts associated with a product or service by assessing the energy and materials used and wastes released to the environment throughout its life cycle.

In this regard, packaging LCA plays a crucial role in identifying stages where environmental impact is most significant, from raw material extraction through material processing, manufacture, distribution, use, and disposal.

Life Cycle Assessment aids businesses and designers in making informed decisions that balance functionality, cost, and environmental sustainability. By applying a robust LCA model, companies can not only reduce their ecological footprint but also meet consumer demand for greener packaging solutions and comply with increasing regulatory requirements on sustainability.

Table of Contents:

1. The Intersection of Ecodesign and Packaging

2. The Life Cycle Assessment (LCA) Framework

3. Ecodesign Principles in Packaging

4. Sustainable Packaging Standards and LCA Outcomes

6. Challenges in Applying LCA to Packaging

7. Conclusion: The Importance of LCA for Future Packaging

Ecodesign integrates environmental considerations from the design and development phases of a product. In the context of packaging, it involves creating packaging solutions that minimize environmental impact while maintaining product integrity and quality. Ecodesign principles are essentially linked with LCA methodologies as both aim to reduce resource use and waste generation throughout a product’s lifecycle.

By incorporating ecodesign practices, packaging can be optimized to use fewer materials, incorporate recycled content, be more energy-efficient during production, and be easier to recycle or biodegrade after use.

Ecodesign in packaging not only addresses the end-of-life stage but also looks at reducing environmental impacts across the packaging’s entire life cycle, aligning with the principles of a circular economy.

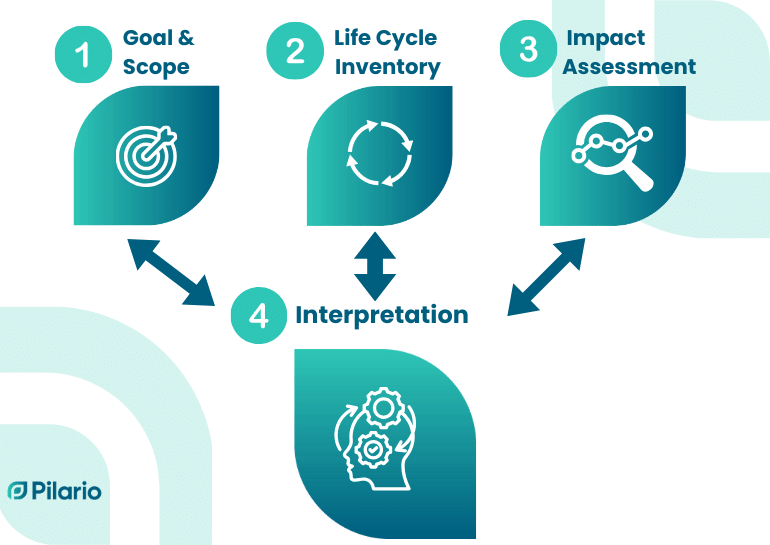

The LCA framework for packaging involves several key steps:

A comprehensive LCA model for packaging should consider:

Ecodesign integrates environmental considerations into product design. The objective is to reduce environmental impact. This is done without compromising quality or performance.

For the packaging industry, this means designing packaging differently. The aim is to use fewer resources and generate less waste. Packaging should be more energy-efficient to produce. It should also be easier to recycle, reuse, or biodegrade.

The principles of ecodesign in packaging can be summarized into several key strategies, let’s explore a few:

Integrating ecodesign and LCA in the development phase of your packaging, involves a holistic approach where environmental considerations are embedded throughout the packaging development process.

This integration can be achieved by:

Life Cycle Assessment (LCA) ratings provide a quantifiable measure of a packaging product’s environmental performance across its lifecycle. These indicators come from detailed LCA studies. They cover 16 environmental impact categories. This includes greenhouse gas emissions, water usage, energy consumption, and waste production. This helps manufacturers, consumers, and regulators compare the sustainability of different packaging solutions based on standardized criteria.

The impact of these indicators on packaging is multi dimensional:

Guiding Design and Procurement Decisions: Companies can use LCA ratings to inform their packaging design choices, selecting materials and designs that have lower environmental impacts.

Marketing and Consumer Awareness: Products with better LCA ratings can be marketed as more sustainable, appealing to environmentally conscious consumers. Multiple Life Cycle Assessment (LCA) platforms provide the opportunity for engagement with all relevant stakeholders through both digital and physical means.

Regulatory Compliance and Certification: Increasingly, governments and industry bodies are setting regulatory standards based on LCA metrics. Packaging that meets certain LCA standards may be eligible for eco-labels or certifications, enhancing its marketability.

Supply Chain Optimization: LCA analysis can encourage companies to look at their supply chains and make adjustments to improve the overall environmental footprint of their packaging.

Various international and national standards guide the sustainable design, production, and disposal of packaging. These standards often incorporate LCA metrics to evaluate environmental impacts. Some of the key standards and certifications are:

Ecolabels: Various countries and regions offer ecolabels that include packaging criteria, such as the EU Ecolabel or the U.S. EPA’s Safer Choice label.

Companies striving for these certifications must often undergo rigorous assessments and make tangible changes to their packaging to comply with sustainability criteria, many of which are grounded in LCA results and LCA analysis.

Implementing LCA in packaging design and production is not without challenges. Common issues include:

Data Availability and Quality: Reliable data on material extraction, manufacturing processes, transportation, and waste management is crucial for accurate LCA model results. However, accessing comprehensive and up-to-date data can be difficult.

Complexity of LCA Studies: Conducting a full LCA can be technically complex and time-consuming, especially when there’s a need to set up an LCA framework. Which can deter smaller companies or those new to sustainability practices.

Interpreting Results: LCA results can be challenging to interpret and translate into actionable strategies. Misinterpretations can lead to incorrect conclusions or suboptimal improvements.

Cost: The cost of conducting a full LCA and implementing changes based on its findings can be significant, particularly for small to medium-sized enterprises.

Consumer Misunderstanding: There is often a gap between the sustainability efforts a company undertakes and the consumer’s perception and understanding of these efforts.

Despite these challenges, there are some strategies companies can help to effectively implement LCA:

Leveraging Industry Databases and Tools:Utilizing existing databases and simplified LCA tools can reduce the need for extensive primary data collection and simplify the assessment process.

Collaborative Initiatives: Engaging in industry-wide or sector-specific initiatives can help companies share best practices, reduce costs, and standardize LCA methodologies.

Focusing on Key Areas: Companies can initially focus on the lifecycle stages or environmental impact categories that are most significant for their type of packaging, which can provide the most substantial gains.

Transparency and Communication: Being transparent about LCA methodologies, assumptions, and results can help build trust with consumers and stakeholders. Effective communication about what an LCA outcome means can also bridge the gap in consumer understanding. Important side note: For the best credibility and compliance, this is crucial in B2B exchanges and competitive comparisons. We’re talking about sticking to ISO 14044 standards. We recommend a thorough peer-review of your data for this purpose.

Incremental Improvements: Rather than striving for perfection, companies can focus on making incremental improvements to their packaging based on LCA findings, which can still lead to significant environmental benefits over time.

In today’s world, understanding the full impact of our packaging choices is crucial. Life Cycle Assessment (LCA) helps us see a more complete picture by analyzing the environmental impacts of packaging from start to finish (cradle to grave).

Combining LCA with eco-friendly design transforms the way we think about packaging. It pushes companies to create packaging that meets our needs without harming the planet.

However, making sustainable packaging is a team effort. It requires cooperation across different fields, from design to logistics, to cut down on environmental impacts. It’s also about clearly communicating the benefits of sustainable packaging to consumers to encourage smarter choices.

There are challenges, though. LCA can be complex, and getting accurate data can be tough. Plus, there’s a gap between what companies do to be sustainable and what consumers understand. It’s important to tackle these issues head-on, being open about how we assess environmental impacts and how we can improve.

This is why companies are now looking for LCA software to help them tackle these challenges. SaaS solutions like Pilario are becoming popular because they make the process much easier. Pilario is an LCA platform designed to simplify LCA analysis. Equipped with ready-made LCA models that fit different industries. This means businesses can integrate sustainability into their strategies more easily, even without an in-house LCA expert.

In conclusion, LCA is more than just a tool – it’s a critical approach for the future of packaging. As we look ahead, we should embrace LCA. It’s not just for compliance or following a trend. Instead, it’s a core principle for creating responsible and sustainable packaging. Our goal is clear: to develop packaging that’s better for the earth and future generations. This development should be guided by the comprehensive insights provided by LCA.

26/01/2024

Uncover the difference between LCA and carbon footprint. Embark on a journey of sustainability with our expert guide!

22/09/2023

Unlock sustainable success with LCA, PEF, and PEFCR. Understand environmental impacts, gain trust, and comply with EU standards effortlessly.

12/01/2024

Explore the Ecodesign for Sustainable Products Regulation's (ESPR) impact on EU product design and sustainability in our guide.