31 August 2023

Unveiling the Future: How Net Zero Meets Digital Twin Technology

In a world coping with climate change and shortages of different resources, the search for long-term answers has become critical.

Net Zero, a concept focusing on balancing the amount of greenhouse gasses emitted with their removal from the atmosphere, has received a lot of attention. Simultaneously, Digital Twin technology, which creates virtual clones of physical assets or systems, is changing a variety of industries. The combination of these two powerful concepts holds immense potential for reshaping industries, urban landscapes and environmental responsibility.

Understanding Net Zero and its Significance

Net Zero represents a crucial milestone in combating climate change. It requires minimizing carbon emissions and offsetting any remaining emissions through actions such as reforestation and carbon capture. This approach is in alignment with initiatives such as the European Green Deal. Achieving Net Zero is vital to prevent further global temperature rise and its catastrophic consequences.

The Emergence of Digital Twin Technology

Digital Twin technology involves creating virtual counterparts of real-world assets, enabling real-time monitoring, analysis, and simulation. Initially very popular in manufacturing, now utilized in sectors like healthcare, urban planning, and aerospace, offering insights that enhance decision-making.

By using Digital Twin technology, businesses can identify and address potential environmental impacts early in the product development process, before they become a problem. This helps to reduce the environmental impact of products and services, and make them more sustainable.

Net Zero Meets Digital Twin: A Symbiotic Relationship

The synergy between Net Zero and Digital Twin technology is evident in their shared objectives. Net Zero and Digital Twin technology can help us reduce emissions and waste, and protect our planet for future generations.

In the world of sustainability, design choices wield immense power, determining a product’s lifespan, materials, repairability, and environmental impact. Surprisingly, decisions made during the design phase determine 80% of a product’s environmental impact (ellenmacarthurfoundation, 2022).

Digital Twin technology enters the scene as a game-changer for predicting a product’s sustainability impact before it’s even created. By creating a digital replica and using Life Cycle Assessment (LCA) simulations, from resource extraction to disposal, we can make informed decisions to minimize environmental harm. This approach, reflecting eco-design, creates products with the environment in mind, ushering in a more sustainable future.

Examples illustrate how digital twin technology is being used for sustainability

Here are some specific examples of how industries are using Digital Twin technology for sustainability :

- The automotive industry is using Digital Twin technology to design more fuel-efficient cars. By simulating the car’s aerodynamics and powertrain, engineers can identify ways to improve its fuel economy.

- The construction industry is using Digital Twin Technology to design and build more energy-efficient buildings. By simulating the building’s energy use, engineers can identify ways to reduce its carbon footprint.

- In the manufacturing industry, companies are using Digital Twin technology to optimize production processes. By monitoring and analyzing the data from the digital twin, manufacturers can identify ways to improve efficiency and reduce waste to enhance their sustainability efforts.

Another great example is a UK research project, funded by a £2.5 million grant from UK Research and Innovation, that aims to develop a digital ‘twin’ of the country using artificial intelligence and big data to aid in achieving its net-zero emissions goal. The project focuses on using AI to reduce emissions from land use, particularly in cattle and sheep farming and degraded peatlands, which contribute about 10% of the UK’s emissions.

Innovative Pathways to Sustainability: Net Zero and Digital Twin

The future of sustainability is being shaped by the powerful synergy between Net Zero and Digital Twin technology. This merging presents an exciting roadmap towards a greener world, where the balance between technological advancement and ecological preservation is achieved through the utilization of real-time data, predictive insights, and forward-thinking solutions.

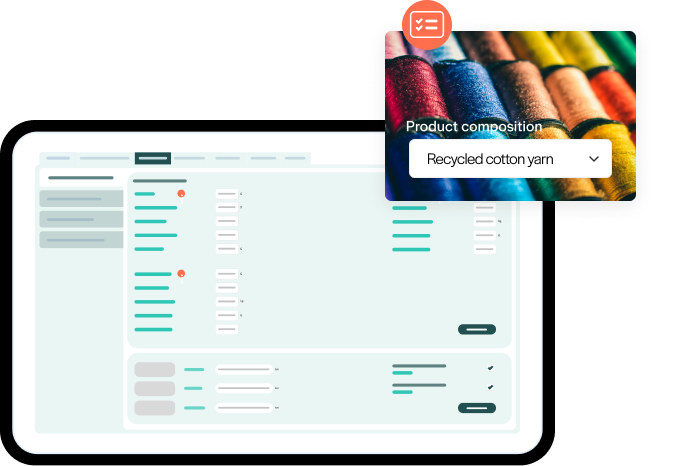

By utilizing a digital twin and LCA software, companies can create a virtual environment that covers the entire lifecycle of a product, integrating Life Cycle Assessment (LCA).

This integration allows businesses to foresee and evaluate the environmental impact of their decisions before they put them into action. From sourcing raw materials to the product’s eventual disposal, this digital setup allows for continuous assessment, aiding in informed and sustainable choices throughout development. This approach not only reduces the need for costly physical testing but also paves the way for greener solutions.

Pilario provides a variety of pre-developed, LCA software solutions that meet compliance standards, allowing you to commence your journey into eco-friendly design.

Curious about learning more? Feel free to contact one of our sustainability specialists.