29 March 2024

Sustainable Packaging: A Comprehensive Guide to Life Cycle Assessment (LCA)

As global awareness rises and demands for environmental stewardship increase, the packaging industry finds itself at a crucial juncture. This guide sheds light on how LCA serves as a powerful tool, allowing businesses to evaluate and enhance the environmental impact of their packaging from cradle to grave.

Understanding and implementing LCA is more than a regulatory compliance measure; it’s a step towards aligning with consumer values, enhancing brand reputation, and fostering a sustainable future. As the industry moves forward, the shift towards eco-friendly packaging is not just beneficial – it’s imperative.

Discover how your business can contribute to a greener planet by embracing LCA analysis and software. Uncover how SaaS solutions like Pilario are changing the process of conducting LCAs, making it straightforward and scalable for companies of various sizes.

Ready to make a change? Let’s explore the transformative journey of sustainable packaging together.

Table of Contents:

1. The Importance of Life Cycle Assessment (LCA) in Packaging

2. Key Stages of LCA Analysis for Packaging

3. Case Studies: Successful LCA Implementation in Packaging

4. How Pilario’s LCA Packaging Model Can Help Your Business

5. Steps to Get Started with Pilario’s LCA Packaging Model

6. Conclusion : LCA Transforming Packaging for a Sustainable Future

The Importance of Life Cycle Assessment (LCA) in Packaging

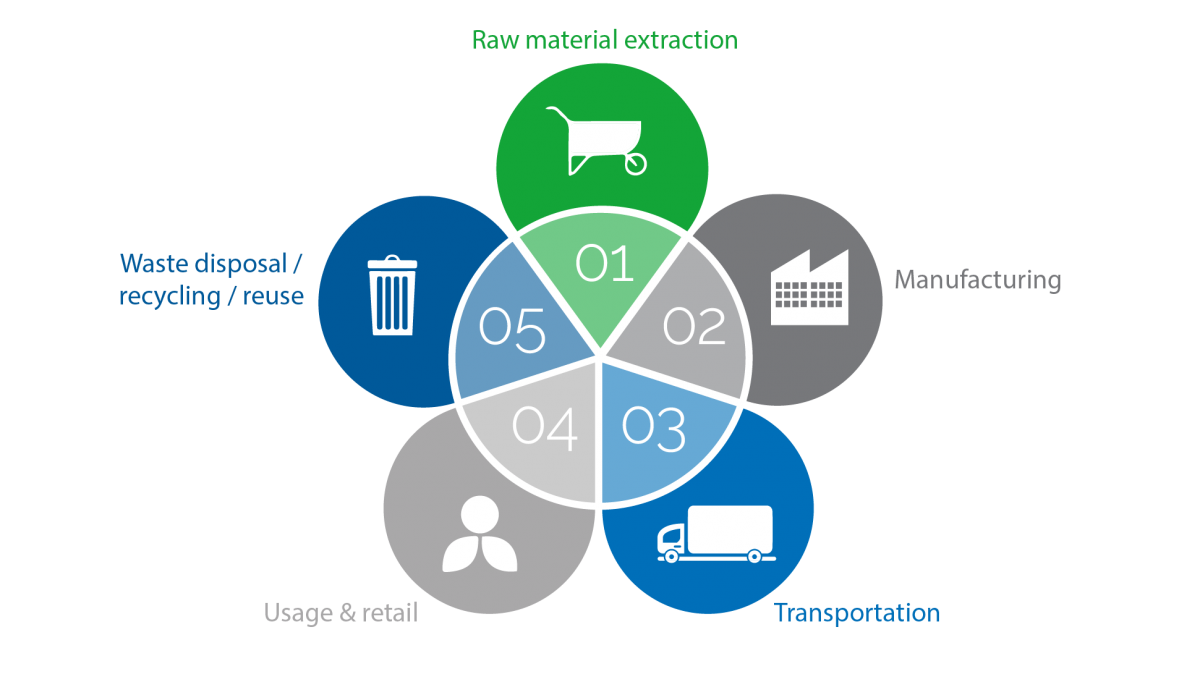

Understanding Life Cycle Assessment in the Packaging Industry

Let us start with quickly explaining the concept of Life Cycle Assessment. Picture LCA as the eco-conscious detective through analysis. When conducting an LCA analysis, it delves deep into every phase of a product’s life cycle – from the extraction of raw materials (cradle) to disposal or, even better, recycling (grave). But it’s not just about mapping the journey, it’s about evaluating the environmental impacts at every stage. Whether it’s the energy consumed, the waste generated, or the resource depleted, there are more than 15 different impact categories.

The importance of Life Cycle Assessment in the packaging industry cannot be overstated. LCA acts as a comprehensive method, providing a framework for evaluating and improving the environmental performance of packaging solutions. In the current climate, where businesses are under increasing pressure due to regulations (e.g. Eu Green Deal, PPWR, …), market demands, and environmental challenges, LCA emerges as an essential methodology for meeting sustainability objectives.

By adopting LCA practices, packaging companies can achieve significant benefits: they not only reduce their environmental footprint but also gain competitive advantages, boost cost-efficiency, and cultivate a positive brand image. Moreover, the varied insights gathered from LCA analysis serve as critical inputs for initiating the eco-design process of products, ensuring that sustainability is integrated at every stage of the life cycle. This strategic approach helps companies to anticipate regulatory changes, meet consumer expectations for greener products, and contribute to a more sustainable future.

Key Advantages of Adopting Life Cycle Assessments (LCA) in Packaging Industry

1. LCA: evaluating the environmental footprint of packaging at each phase

Life Cycle Assessment (LCA) offers a complete look at the environmental impacts of your packaging solution, taking into account elements like carbon footprint, energy use, water use, and the creation of waste. This broad method makes sure we examine all important environmental factors, resulting in better and more sustainable packaging options.

2. Data-driven Decisions

Using Life Cycle Assessment (LCA) helps companies make smart choices with quantifiable data. It evaluates the environmental effects from start to finish of packaging, helping businesses find where to get better – like choosing eco-friendly materials, optimizing manufacturing processes, or enhancement of recycling practices.

3. Meeting market demands and regulatory standards through LCA

As rules to protect the environment get stricter and more shoppers want green products, Life Cycle Assessment (LCA) becomes essential for following the law and staying ahead in the market. Eco-friendly packaging, as shown by LCA, is more likely to meet these new standards and attract people who care about the planet.

4. Cost Reduction and Efficiency

Implementing LCA can lead businesses to save money. It finds less efficient areas in the packaging process, allowing companies to cut down on waste and use resources better. This makes their packaging methods more effective and cost-effective.

5. Building consumer trust and enhancing brand image

Companies using LCA to create and assess their packaging can boost their brand and win customer trust. Showing you care about the environment with LCA can make your brand stand out and attract shoppers who prioritize sustainable packaging.

Key Stages of LCA Analysis for Packaging

For businesses focused on greener packaging, mastering Life Cycle Assessment stages is crucial. This means examining everything from material sourcing to disposal or recycling. LCA pinpoints key improvement spots for eco-friendly choices. Let’s explore the packaging LCA stages.

- Goal & Scope Definition

Start by defining the LCA’s aim and limits for your packaging. Decide whether to focus on single-use or reusable options and the type of materials like plastic, glass, cardboard,.. Clear goals help keep the study on track. - Inventory Analysis (Life Cycle Inventory or LCI)

Next, gather data for the Life Cycle Inventory (LCI). Document all inputs and outputs, like raw materials, energy consumption, water use, emissions, .. during the packaging lifecycle. Accurate data is key for a solid foundation for the next steps. - Impact Assessment (Life Cycle Impact Assessment or LCIA)

Then, assess the environmental impacts in the Life Cycle Impact Assessment (LCIA). Understand how different stages affect issues like climate change and resource use. This helps identify critical areas for improvement. - Interpretation

Finally, analyze the LCIA results in the Interpretation stage. Highlight the main findings and suggest ways to reduce the packaging’s environmental impact. This could include suggestions for material substitution, process improvements, or end-of-life management strategies. The interpretation phase is crucial for making the assessment actionable and guiding sustainable packaging strategies.

Case Studies: Successful LCA Implementation in Packaging

Uncover the tangible outcomes of effective LCA integration with insights from these industry case studies. Starting of course with one of our own.

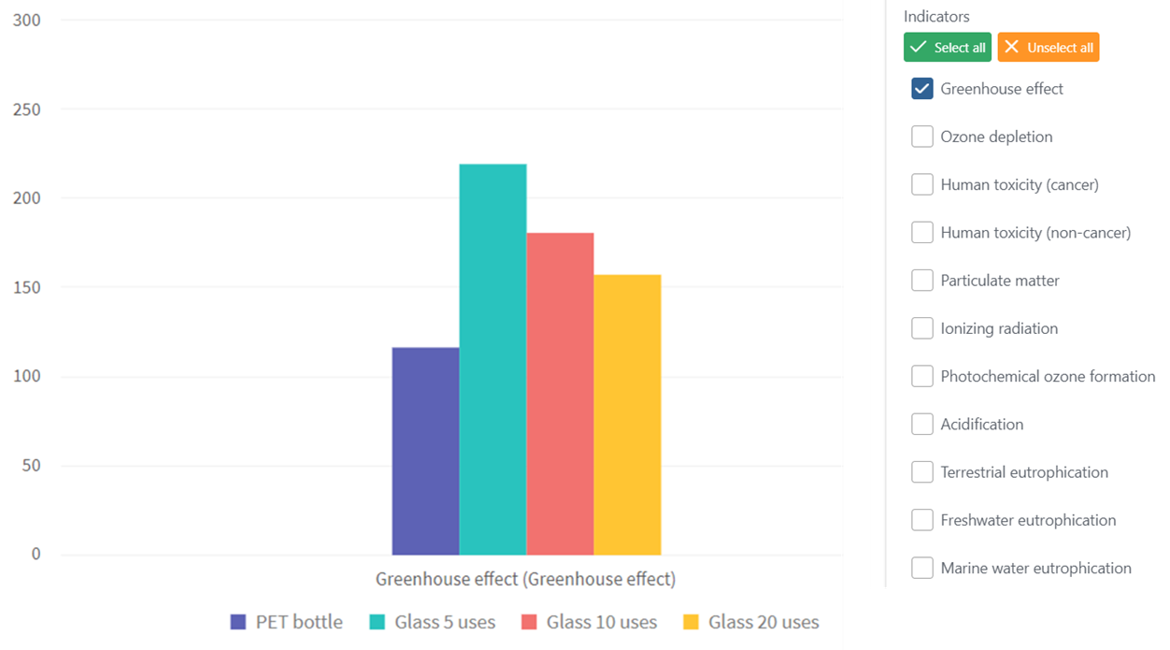

Case Study 1: PET vs. Reusable Glass: Uncovering True Environmental Impact with LCA analysis

The discussion on choosing between traditional plastic (PET) bottles and refillable glass bottles highlights widespread misunderstandings about environmental impacts. People tend to favor banning plastic, linking it to ocean pollution and damage to biodiversity. The most common solution appears to be replacing plastic with materials such as glass. Yet, this approach fails to consider essential LCA considerations, especially the carbon footprint.

Process: Utilizing Pilario’s LCA Packaging model, our client could compare the environmental impacts of a one-liter PET bottle against a one-liter refillable glass bottle across various scenarios. Our LCA software required minimal initial data, such as bottle weight, recycled content, transport distance, and, uniquely for glass, the number of uses. The default settings provided by Pilario allowed for a quick preliminary assessment, which would later be refined with more specific supplier data.

Results: The initial findings were revelatory. Despite the well-intentioned switch to glass, the environmental impact, particularly regarding CO2 emissions, was significantly higher for the glass bottles compared to their PET bottles, even after accounting for multiple reuses (5, 10, and 20 cycles). This impact was primarily due to the higher energy requirements in producing and transporting the heavier glass bottles.

Important sidenote: When the PET bottles are recycled in the corrected bin.

The LCA analysis through Pilario’s LCA Packaging model enabled our client to implement eco-design strategies and reevaluate the “anti-plastic” scenario with solid evidence, resulting in more sustainable solutions. This case highlights the importance of data-driven decisions and LCA thinking, enabling businesses to question prevalent environmental misconceptions leads them toward genuinely beneficial environmental practices, thereby enriching the understanding of sustainability in packaging.

Case Study 2 : Microsoft’s Sustainable Packaging Revolution

In their journey to achieving carbon negativity by 2030, Microsoft embarked on a transformative mission to eliminate single-use plastics from their packaging by 2025. Recognizing the environmental toll of conventional polyethylene bags used in their hardware product packaging, Microsoft targeted these as a key area for improvement.

Challenge: The standard polyethylene bags, akin to bread bags, served to protect retail packages but contradicted Microsoft’s sustainability commitments. Initial attempts to eliminate these bags revealed potential harm to product safety, prompting the search for an eco-friendly alternative.

Solution: Microsoft’s team discovered an alternative in glassine paper, a more sustainable option. Before making the switch, the team conducted a thorough environmental impact analysis comparing the traditional polyethylene bags to the new glassine paper solution.

Outcome: The transition to glassine paper resulted in significant environmental benefits, including an 85% reduction in fossil fuel use and a 69% decrease in water consumption compared to the LDPE bags. This change not only aligned with Microsoft’s environmental goals but also led to cost savings. Successfully implemented in 2021, this initiative demonstrated Microsoft’s commitment to sustainable packaging and set a precedent for reducing single-use plastics. (Source: https://sustainablepackaging.org/)

How Pilario’s LCA Packaging Model Can Help Your Business

In today’s market focused on ecology, companies understand the vital importance of Life Cycle Assessment (LCA) for sustainable packaging.

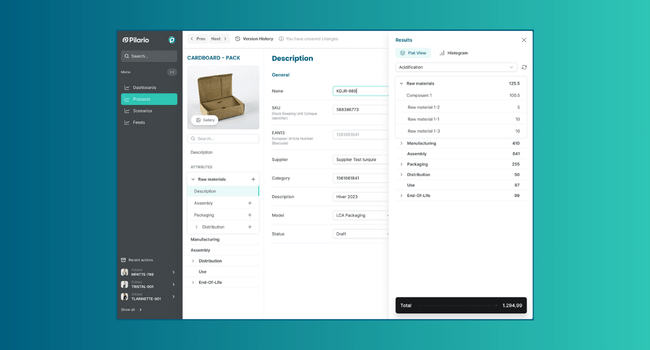

SaaS solutions like Pilario are transforming how packaging companies conduct LCA Analysis, making the application of LCA to your packaging scalable and straightforward, thus enabling the integration of sustainable practices throughout your entire product portfolio. With the overall goal to make sustainability a cornerstone of your business strategy.

Our SaaS solution provides a range of predefined LCA models, with a specific LCA packaging model. Tailored for different materials like plastic, glass, cardboard, and metal, while being compliant to ISO 14040 and ISO 14044 LCA standards. And transforming the principle of eco-design from a mere concept into tangible practices, enabling you to save and compare different scenarios, benchmark, and optimize your current packaging for improved sustainability.

Overall our approach enhances sustainability efforts in the packaging industry by offering automated, transparent reporting tools that display your environmental efforts both online and offline. By meeting and exceeding environmental and consumer expectations, our solutions ensure your packaging practices are up to industry standards. This practical application of LCA allows for better material selection and process enhancements, embedding sustainable development throughout your packaging’s lifecycle, thus boosting your market position and catering to the demands of environmentally conscious customers.

Steps to Get Started with Pilario’s LCA Packaging Model

As mentioned before, adopting the Pilario LCA Packaging Model can significantly enhance your packaging approach with sustainability in mind. Let’s explore step-by-step how you can integrate Pilario into your business strategy.

- Sign Up for Pilario

Register for Pilario and explore our extensive collection of predefined LCA models for a range of different industries. Pick the LCA packaging model. Choosing the right model is crucial as it forms the base of your LCA analysis, making sure your evaluation is precise and suited to your packaging. This key step helps meet industry norms and consumer demands for sustainability. - Gather Your Data

The accuracy of your LCA depends on the data you input. Gather detailed information on your packaging, including materials, weight, and recycled content. This ensures your analysis is specific and relevant to your sustainability goals. - Fill in Your Data

Pilario prompts you to input company-specific or site-specific data that’s easily accessible and significantly influences your LCA results. For any other parameters, Pilario utilizes the most recent databases to fill in default data, ensuring your analysis is grounded in up-to-date and relevant environmental impact assessments. - Calculate the Environmental Footprint

Use Pilario to calculate your packaging’s environmental footprint, no prior LCA expertise needed. Results are meticulously broken down by lifecycle stage, spotlighting the “hotspots” where improvements can significantly reduce your environmental impact. - Start Eco-designing Your Packaging

Pilario isn’t just about assessment; it’s a tool for action. Once your packaging is modeled, you create and save different scenarios for eco-design purposes. Experiment with lightweighting, logistic alterations, or material changes to discover packaging versions that minimize environmental impact. - Export and Share Your Results

Boost trust and loyalty by openly sharing your green achievements with Pilario. Easily send out your automated LCA reports. Show off your eco-friendly packaging by sharing your environmental scores with QR codes or iframes. This not only demonstrates your sustainability efforts but also elevates your brand in the eco-conscious market.

Conclusion : LCA Transforming Packaging for a Sustainable Future

Starting the journey toward sustainable packaging requires learning Life Cycle Assessment (LCA), which is a critical step for businesses all over the world. LCA acts as an extensive method, examining a product’s life cycle from creation to recycling, guiding firms towards environmentally friendly packaging decisions.

Adopting LCA can significantly shrink environmental footprints, boost market position, cut costs, and improve brand reputation. It also helps businesses stay ahead, meeting changing consumer needs and regulatory standards while nurturing a sustainable and innovative environment.

In today’s market, facing demands for eco-responsibility and consumer expectations, LCA becomes vital. It allows companies to rely on solid data, refine operations, and shift to eco-friendlier packaging, aligning with modern consumer values and regulatory requirements.

Embrace Sustainability with Pilario: Transform Your Packaging Today

Ready to redefine your packaging with sustainability at its heart? Pilario is your partner in this essential transition. With Pilario’s dedicated LCA packaging model , conducting a detailed environmental footprint analysis of your entire product portfolio becomes a straightforward task, allowing you to make data-driven decisions effortlessly.

Join the ranks of businesses making informed, eco-conscious decisions to benefit our planet. Sign up for Pilario now and transform your packaging into a beacon of sustainability.

Questions? Thoughts? Book your meeting today.

FAQ

1. What is Sustainable Packaging and why is it important?

Sustainable packaging uses environmentally friendly materials and processes to minimize its ecological footprint, including renewable, recyclable, or biodegradable options. Its significance lies in reducing waste, conserving resources, and decreasing pollution, thereby contributing to a healthier planet and aligning with global sustainability efforts.

2. How does Life Cycle Assessment (LCA) apply to Sustainable Packaging?

Life Cycle Assessment (LCA) evaluates the environmental impacts of packaging throughout its life cycle, from material extraction to disposal. It helps identify the most ecologically friendly options by analyzing carbon emissions, energy, water use, and waste production, guiding businesses towards more sustainable packaging decisions.

3. What are the key benefits of using Sustainable Packaging?

Adopting sustainable packaging offers environmental benefits by reducing pollution and resource use, economic advantages through potential long-term cost savings, and social gains by improving brand image and meeting consumer demand for eco-friendly practices. It also supports compliance with evolving environmental regulations.

4. What challenges are faced in the adoption of Sustainable Packaging?

The shift to sustainable packaging can encounter hurdles such as higher initial costs, the need for supply chain reconfiguration, technological limitations in production and recycling, and the challenge of consumer and market acceptance. These factors require careful consideration and strategic planning for successful implementation.

5. What are the latest trends and innovations in Sustainable Packaging?

Emerging trends in sustainable packaging include the development of biodegradable and compostable materials, edible packaging solutions, and the use of plant-based resources. Innovations also focus on designing packaging with recycling in mind, enhancing the efficiency and effectiveness of recycling processes and contributing to the circular economy.